How SQP Engineering leverages automation to operate 24/7

Reliable Output, Day and Night

SQP has always had a remit to stay up-to-date with the latest automation and technology to maximise the quality of our output. It is about ensuring continuous, reliable production.

Early on, we decided to invest technology to keep our equipment running 24/7 for ‘lights-out manufacturing’—long after the tools are down on Friday afternoon. Our recent investment in additive manufacturing is the latest step, as it allows automated manufacturing of high-strength industrial parts.

In our Bibra Lake facility we have three automation cells with Fanuc robots at the core of this automation strategy. These machines have been added one by one in response to ongoing demand – starting with the first 10 years ago in 2013. They support an uninterrupted workflow with fast turnaround and high quality.

David Miller, owner of SQP, worked closely with Automated Solutions Australia (ASA) on the design of each of these cells, keeping specific pain points and outcomes in mind:

“The dream was always ‘lights out’ production, where the cells can continue production through the night unsupervised, increasing productivity and allowing the company to meet tight deadlines” – David Miller, SQP

Achieving Precision through Automation

The beauty of automated equipment is that it can produce parts without intervention. It is programmed to allow for rapid changeovers and continuous operation. All we need to do is ensure more materials are ready to go once the job is completed.

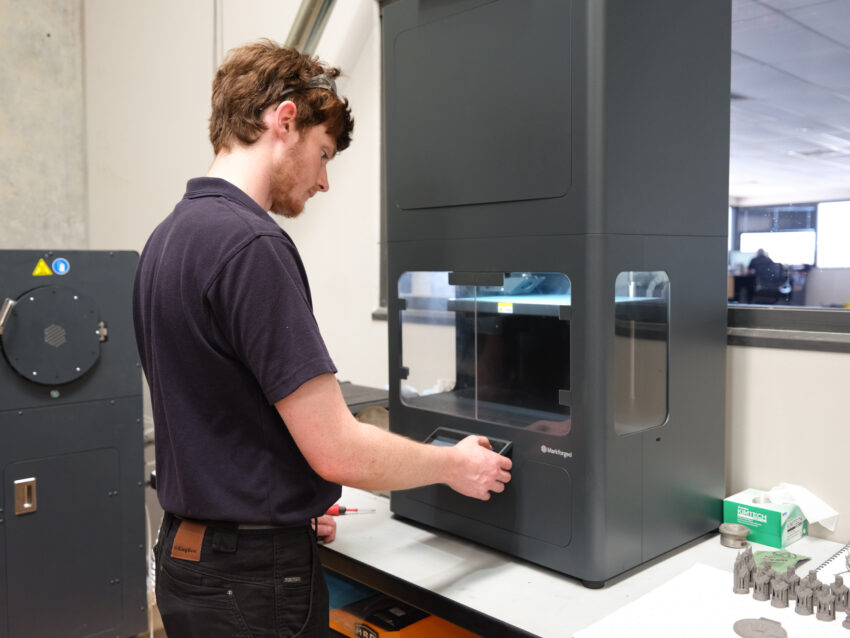

We have recently expanded our automated equipment in both robitic automation and 3D printing. The latest are our Fanuc M20iD/25, tending to an Okuma LB 3000. On the industrial 3D printing side, we have our Markforged FX20, capable of unattended additive manufacturing. The Markforged Metal X and Sinter, is equipped for all things metal 3D printing.

By leveraging automation, we can consistently produce parts with high quality using each of these machines.

The Importance of Adaptability in Automation

Automation might make you think of a repetitive process pumping out thousands of the same item. However, our setups prioritise flexibility. The different robotic cells, CNCs and industrial 3D printers offer the adaptability needed to meet a mix of manufacturing requirements.

The industrial 3D printers are well suited to small batches or one-off parts, and our robotic automated manufacturing is suitable for larger batches. Robotic automated manufacturing is best used for 10 parts or more, at which point it will usually have tangible throughput and cost benefits.

This level of flexibility enables us to cater to smaller-scale bespoke projects and larger-volume production runs.

Maintaining Quality with Automation

Maintaining high-quality standards is key for automated environments. We adhere to guidelines backed by our ISO 9001 accreditation and our controlled metrology room is equipped with tools for critical inspections.

We thoroughly examine each part in this space to ensure it complies with the required specifications. Our Micro Vu Excel Measuring Center and InSpec Metrology Software® are key in using advanced optical and imaging technology for generating reports and guaranteeing that every component meets the specified dimensions and the highest quality standards.

Quality Assurance Experts

Even with this level of automation, we recognise the value of human involvement in our overall process and, particularly, our quality control processes. At SQP, two dedicated quality assurance experts oversee Micro Vu and our manual quality control processes.

The team’s expertise is utilised to oversee and manage our quality assurance process, ensuring additional manual inspections are carried out whenever necessary.

How does all of this benefit you?

The objective behind our round-the-clock operations is to provide solid benefits for our customers. These advantages include;

- Reduced Lead Times: Our continuous manufacturing processes enable us to complete and deliver products in the shortest possible time frame.

- Scalable Production: Whether demand spikes unexpectedly or gradually increases, our equipment has the flexibility to adapt and meet production requirements without compromising timelines or quality.

- Cost-Effective Solutions: By optimising machine usage and minimising manual intervention, we achieve cost savings that we pass on to our clients. Our aim with automated manufacturing is to offer competitive pricing without compromising on quality.

- Consistent Quality: Our rigorous quality control systems and advanced automation equipment consistently deliver parts that meet or exceed industry standards.

- Transparent Quality Reporting: Upon request, we provide inspection reports that offer clients comprehensive information about their product’s conformity to specifications.

Looking Ahead

As we look ahead, we continue to invest in technologies that enhance our 24/7 manufacturing capabilities.

Our goal is to stay ahead of industry trends and provide our clients with the advantages of quick production cycles, guaranteed quality and adaptable manufacturing solutions.

Through ongoing investment in cutting-edge technology and assembling a talented workforce through our existing team and apprentice program, we aim to become a frontrunner in automated precision manufacturing.